MacDermid Alpha Electronics Solutions, a global supplier of integrated solutions from our Circuitry, Assembly and Semiconductor divisions that provides unmatched capabilities in electronics design and manufacturing, has announced that its electro-chemicals brand, Electrolube, will be exhibiting at the Battery Show North America on booth #1211 at the Suburban Collection Showplace, Novi, Michigan on the 13th-15th September.

As demand for electric and hybrid vehicles continues to rise, battery systems increasingly require protection from harsh environments. Specialist electro-chemical materials are required to cope with the harsher environments and meet the demanding requirements of high-capacity, fast charging battery packs. Consequently, battery performance, safety and reliability can be significantly improved. Electrolube, global leaders in protective electro-chemical solutions, will showcase thermal management solutions, encapsulation resins and conformal coatings on booth #1211. Global Product Manager for Resins, Beth Massey, will be available during the show to assist visitors with their battery protection requirements.

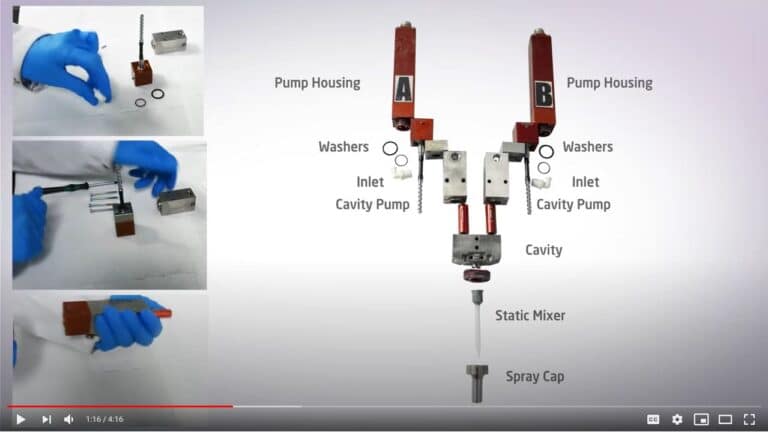

Key products for battery protection include Electrolube’s thermal gap filler, GF400, which is a highly effective heat transfer solution with outstanding thermal performance at 4.0 W/m.K . The two-part, liquid silicone-based gap filler is designed for applications where the gap between the component and the heat dissipating surface is larger than a traditional thermal interface. This makes GF400 ideal for EV battery applications where there are significant gaps between cells. The thermal gap filler also prevents the pump-out phenomenon, due to its low modulus elastomer that forms after curing. It is designed for use with higher thickness than a standard thermal interface material but also maintains its stability at these higher thicknesses, ensuring efficient and reliable heat transfer. With a wide operating temperature range between -50 to +200°C and non-flammable, GF400 is a dispensable material that can be applied to help dissipate heat from even the most complex geometries. The properties of GF400 make it one of the highest performing thermal management products for managing heat dissipation.

To prolong battery life and increase efficiency, the ER2221 Thermally Conductive Epoxy Potting Compound is ideal for potting cells within electric vehicle batteries and can assist with securing cells in place whilst dissipating the heat away to the surroundings.

The fast-curing epoxy resin, ER2223, has a wide operating temperature range of -40°C to +180°C and has been specifically formulated to meet the harsh operating conditions of under-hood applications in the automotive industry. It is chemically resistant to most fluids found in the engine compartment of vehicles and offers excellent protection to electronic components.

Designed for gap filling applications, HTCPX Non-Silicone Heat Transfer Compound PLUS Xtra provides the ultimate in thermal conductivity at 3.40 W/m.K. HTCPX is electrically insulative, ensuring that leakage currents cannot be formed if the paste should encounter other parts of the assembly. With a wide operating temperature range from -50°C to +180°C, HTCPX is vibration stable, low in toxicity and upholds excellent non-creep characteristics.

Beth Massey, Global Product Manager for Resins, comments, “The Battery Show North America presents us with a unique opportunity to connect with the EV battery industry and showcase our proven resin, thermal management and coating solutions for improving battery reliability and performance. Our broad range of electro-chemical products safeguard every aspect of an EV battery system to ensure our customers can tick every box when it comes to safety, reliability, and performance. We are looking forward to meeting visitors during the event, to learn about their requirements and help advise them on the efficient solutions we offer.”

Also featured at Booth #1211 will be the ALPHA Argomax suite of advanced sinter and solutions for die attach and package attach, which significantly enhance the range, performance, and reliability in traction inverters.

These engineered sinter materials are proven to enable high throughput and reliability while providing flexible and easy-to-use form factors that reduce the capital cost and accelerate time to market.