Electrolube’s Senior Technical Manager, Beth Turner, picks up the thread of her previous blogs, to describe where resins are currently playing a vital role in the modern world, while also offering an insight into their thermal conductivity, suitability for RF applications and exploring a new era of bio-based encapsulation resins that not only improve the environment at large, but also end-use reliability and increased consumer satisfaction…the performance of these next generation eco resins is a must-read, so without further ado, let’s get straight into our five-point format.

1) Thermally conductive encapsulation resins – Why would you use one of these over a conventional thermal paste or TIM?

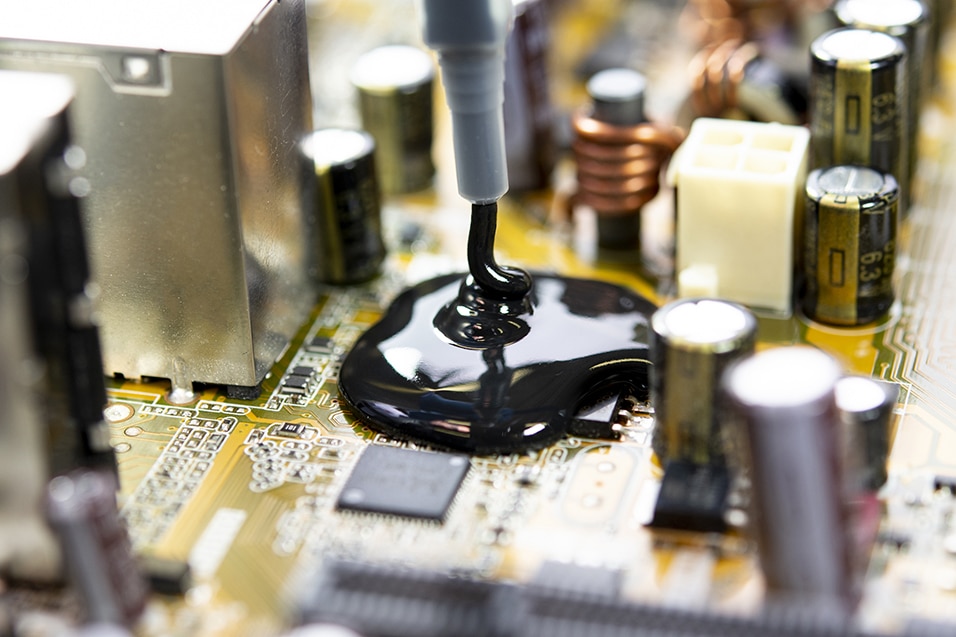

Thermal pastes are often applied between heat generating components and heat sinks to maximise heat transfer, improve device reliability and extend lifetime. This is due to their high thermal conductivity values and, when applied as a thin bond line, they exhibit low thermal resistance. By applying a thin, uniform layer of a thermal interface material, it is possible to obtain the maximum efficiency of heat dissipation. It is also important to consider the operating temperature conditions; in the case of LEDs where devices are switched on and off regularly, this results in the unit going through a thermal cycle, heating up once switched on and cooling again when powered down. Over the lifetime of the product, many thermal cycles take place and this may affect the positioning of a thermal paste over time. In other words, a poorly formulated paste can migrate over time and reduce the efficiency.

Thermally conductive resins can be used as an alternative solution to ‘keep things cool’, such resins also provide lots of other value-added benefits such as mechanical protection. If protecting components from mechanical shock and vibration are a concern, then a thermally conductive encapsulation resin is likely to be the best solution as it adds a level of stability(?) that helps to insulate the potted components against adverse mechanical movements. The arch-enemy of electrical and electronic devices is the dreaded ‘moisture’; on top of producing short-circuits, moisture also causes corrosion, which leads to premature deterioration of components. You might also need to protect electrical or electronic components from encountering chemicals, including acids, alkalis, solvents, and other substances that pose a threat to delicate circuits and components. Encapsulating with a thermally conductive resin will help to ruggedize against all these harsh external factors. Lastly, it’s worth citing that, aside from providing all the protections listed above, opaque potting and encapsulation resins also conceal what lies beneath. This could provide an effective foil against counterfeiters or those wishing to copy a circuit layout, helping you to protect your intellectual property.

2) Which chemistry (if any) lends itself to thermal conductivity – i.e. epoxy, PU or silicone?

Epoxy, polyurethane, and silicone chemistries are all capable of producing resins with high thermal conductivity values. The thermal conductivity is dictated by the type of filler used, particle size, particle size distribution and morphology. When these four factors are carefully considered as part of the product design, you get encapsulation resins with high thermal conductivity values, irrespective of the reactive chemistry that hold the filler in place.

From the Electrolube range, ER2220 provides the highest level of thermal conductivity combined with environmental protection afforded from the encapsulation process. This highly-filled epoxy resin possesses very high thermal conductivity, 1.54 W/m.K. Thermal conductivity, measured in W/m.K, represents a material’s ability to conduct heat. Bulk thermal conductivity values give a good indication of the level of heat transfer expected, allowing for comparison between different materials. Electrolube, part of MacDermid Alpha Electronics Solutions, utilise a Modified Transient Plane Source (MTPS) method, amongst others, to provide accurate comparisons of bulk thermal conductivity. Note there are different methods to determine Thermal Conductivity so remember that when comparing datasheets from different suppliers.

3) Apart from the obvious assumed benefit to the environment, what other benefits could be expected from bio-based resins and are there more to come from Electrolube?

There are lots of observed benefits to using bio-based resins aside from the obvious environmental credentials. Research has shown that quality of performance can be significantly improved. Resins where the reactive component is derived from biobased feedstocks can have improved performance in harsh environments, particularly their electrical insulation in hot humid conditions compared to reactive components derived from crude oil. Comparing biogenic powders with mineral rock powders shows that bio-sources can be used to effectively dissipate heat away from high power density devices and shows improved protection in underwater environments.

There can also be health and safety benefits, for example, the curing agent or hardener typically used for Polyurethanes is based on Methylene Diphenyl Diisocyanate (MDI), crude oil is a crucial raw material for the synthesis of MDI. MDI is a respiratory sensitiser and harmful if vapours are inhaled, from a H&S label perspective it contains the “exploding chest” pictogram (GHS08/ health hazard). We can replace this hardener with alternative reactive agents derived from bio-sources which do not contain the GHS08 pictogram and are much safer for operators to use.

4) Do bio resins lend themselves to RF applications?

They most certainly do. Electrolube UR5645 has a bio-sourced content of over 60%, this is an unfilled polyurethane resin and has found success in sensor applications as it has a low dielectric constant (relative permittivity). Most IoT communication takes place in blocks of the radio frequency spectrum, a low dielectric constant is essential to ensure the resin does not interfere with the RF signal. UR5645 provides excellent electrical insulation across a wide operating temperature range, required for long-term performance, and has a high toughness offering protection from physical shock and vibration. It has good resistance to lots of deleterious substances making it the ideal choice for ruggedizing sensors exposed to harsh environments.

5) What sort of testing programmes have these new bio resins been subject to?

The bio-resins have been tested extensively. There is a common perception that going green, or bio-based, means there will be some sort of compromise on quality of performance. For a new product line to be relatively disruptive and have a high bio-derived content, extreme testing was essential to generate valuable data. The barriers to entry for encapsulation resins in the electronics market is relatively low when compared with other ruggedization techniques such as conformal coatings. Typically, a lot of resin qualification comes down to customers screening for their own unique application, the resin either passes or fails. There is no formal ‘industry standard’ that outlines a specific test criterion, this is mainly because every application is truly unique.

To recall just a handful of the tests these new bio resins have been subject to: Surface Insulation Resistance Testing (SIR) on copper and tin B-24 test coupons at 85°C/85% RH, to ensure the encapsulant remains electrically insulative in hot humid conditions; Volume Resistivity before and after immersion in water and salt water to ensure the bulk material remains electrically insulative in underwater applications; Thermal Shock Testing, -40°C to +85°C for plastic housing and -40°C to +125°C for galvanised steel housing, to monitor for any cracks or loss off adhesion in this accelerated life test; 1000 hour thermal ageing was performed on type IV specimens in accordance with ASTM D638; The tensile strength and elongation were measured before and after high temperature exposure for 100, 500 and 1000 hours to monitor the consistency in physical performance with long term exposure to high temperatures, to determine the maximum operating temperature. Numerous accelerated life tests have been performed to evaluate the performance of novel bio-based materials alongside commercially available resins derived from crude oil and mineral rock powders. Comparison of data concludes that going ‘green’ can deliver performance advantages in underwater applications as well as hot and humid operating environments.

Resins play an integral part in ensuring that an electronics product can survive for at least its design life, and often well beyond. Be it chemical, physical, or thermal, whatever the conditions, there is a resin system that can be found or developed to provide the protection required. I hope you have enjoyed learning more about the benefits of bio-based resins and what they can bring to your applications. Over the coming months I hope to provide more useful tips and design advice that will help make life a bit easier for those who are responsible for making the decisions on protecting components and circuitry.