As we are all aware, smart Cities are quickly evolving and a key part of this IoT revolution is sensor technology. We have recently collaborated with a customer on a new smart car park sensor application with great success. You may ask, “why do we need a smart car park?”, and the simple answer is because it helps reduce pollution and actually makes better use of our own time. Smart car parks aim to eliminate the endless circling of cars looking for an empty parking space and will create a more convenient, less stressful experience for drivers. In this application, the sensor technology is deployed to direct drivers to available parking spots, it shows empty spaces on maps and offers directions to reach them. The sensors detect movements within the car park and can detect cars as they enter and leave, enabling the system to calculate the number of vehicles present in real-time.

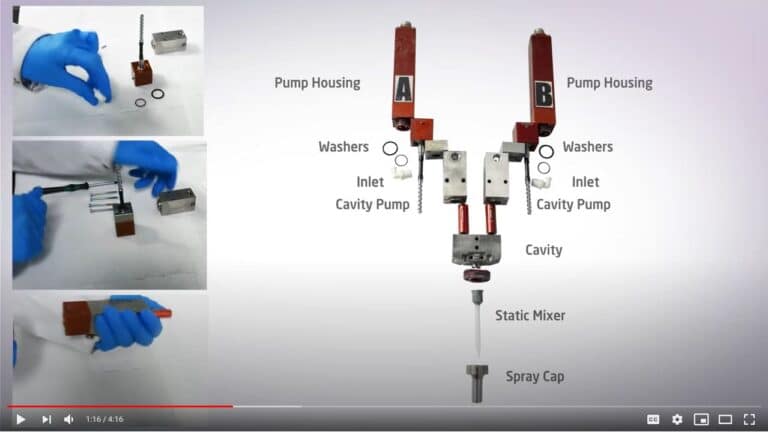

Our challenge was to provide a protection solution to pot domed shaped sensors within a car park floor. The sensors needed a heavy-duty solution to endure cars driving over them and be resistant to temperature extremes and water ingress, but also allow effective RF communication, whereby the signal can travel through the sensor as well as the resin.

The unit’s original material from a different provider wasn’t robust enough to withstand the impact of cars driving over it. Also, the surface energy of the housing material was too low to allow good wetting of the resin and subsequently lead to insufficient adhesion, which caused the unit material to bend, resulting in delamination and water ingress inside the unit. The required resin needed to be low viscosity to fill all gaps in the small unit, show good adhesion to the material of the unit and provide protection at low temperatures during the winter and high temperatures during the summer.

Following our recommendations, the unit’s design, hardness and housing material were changed. We used the UR5118 polyurethane resin to avoid RF interference and provide a dielectric constant of between 3-4 @50Hz. The UR5118 has a viscosity of 2300@ 23°C and 860@ 60°C, which ensures sufficient flow in small gaps. It has a wide temperature range -60 to +125 °C and a low exotherm (<35°C). With a shore hardness of A80, the UR5118 is gentle to more delicate components whilst providing good impact resistance. The reformed unit was tested with the new UR5118 resin and passed all tests.

As a brand, MacDermid Alpha Electrolube thrives on delivering the very best solutions per individual application. The UR5118 resin is becoming a high-demand resin product for IoT applications, due to its proven capability of protecting RF transmitters, sensors and circuitry from harsh environments, vibration, temperature extremes and water ingress. If you have an application that you may require some support with, please contact our Technical Support team who will be happy to make some suggestions for you. We also develop bespoke solutions for customers with specific requirements.