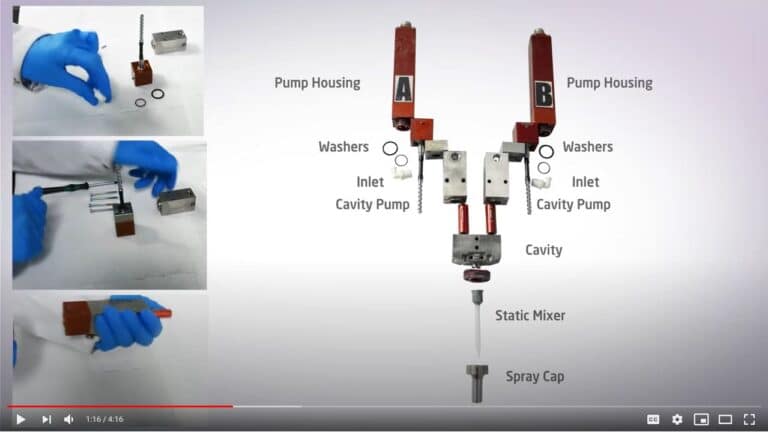

Electrolube Resin Packs come in pre-measured packs ready to use. In this example video we are using a 250g resin pack, but the process is essentially the same for all pack sizes regardless of the mix ratio.

It is Important with a Silicone, not to remove the resin pack from the aluminium foil until immediately before use to avoid moisture ingress.

To begin the mixing process, remove the pack from its packaging and gently pull apart the pack so that the clip pops open.

This allows the two parts of the resin pack to combine.

Using the removed plastic clip, push all of the part A into the Part B section, and begin mixing by moving the resin around in the bag with your hands.

To ensure the two parts mix thoroughly, use the clip to push the resin together, ensuring as little as possible sticks to the pack sides.

This is best achieved on a perfectly flat surface so as to avoid any material sticking to the pack sides and avoid the risk of grit on the surface splitting the pack.

Continue mixing and repeat this process for around 2 -4 minutes until the resin is full mixed. Continuing for longer on the bigger pack sizes.

The Resin is then ready to use.

The corner of the pack can be cut to act as a simple dispenser.

Pour the resin against the edge of the unit to avoid trapping air under the PCB and allowing the resin to flow under the board pushing air out.

We would usually advise that the unit is cleaned before application of the resin.